Performance and application of material ST37: the material has good performance, that is, through cold rolling, it can obtain cold rolled strip and steel plate with thinner thickness and higher precision, with high straightness, high surface finish, clean and bright surface of cold rolled plate in Taiwan Strait, easy to be coated, various varieties, wide application, high stamping performance, non aging, and low yield point.

1020 belongs to high-quality carbon structural steel. Its strength is slightly higher than 1015 steel. It has good toughness, plasticity and weldability. It is rarely quenched and has no temper brittleness. Parts with high cold deformation plasticity, generally used for bending, calendering, edge bending and hammer arch processing, good welding performance of electric arc welding and contact welding, small thickness during gas welding, strict shape requirements or complex shapes are prone to cracks. Machinability cold drawing or normalizing state is better than annealing state, and is often used to manufacture various mechanical parts with low stress and high toughness requirements.

Due to moderate carbon content and good comprehensive properties, the strength, plasticity, welding and other properties are well matched, which is the most widely used. SS400 steel plate is applicable to bridges, ships and vehicles.SS400 is often rolled into wire rod or round steel, square steel, flat steel, angle steel, I-beam, channel steel, window frame steel and other section steel, medium thick steel plate. It is widely used in buildings and engineering structures. It is used for making steel bars or building workshop frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc., and is also widely used as mechanical parts with low performance requirements; C. Grade D steel can also be used as some professional steel.

S235JR is a European standard non alloy structural steel, which is equivalent to the national standard Q235B, that is, carbon structural steel with low carbon content. It is widely used for welding, bolting and riveting structures. It can also be used for building, bridge, ship, vehicle structural parts, manufacturing various tools, cutting tools, molds and measuring tools.

SPCE is suitable for deep drawing grade steel.Cold rolled steel is our most common and commonly used cold rolled products.Its brand can be generally divided into: SPCC, SPCD, SPCE.

SPCE is suitable for deep drawing grade steel.

1. Width: 600-1000 mm 2. Thickness: 0.135-2.0 mm 3. Hardness: T2, T2.5, T3, T4, T5, T6, T7, DR8, DR9 4. Standard: AISI, ASTM, BS, DIN, GB, JIS 5. Grade: SGCC, SGCH, SGCE, SPCG, DX51D, 6. Technique: cold rolled 7. Coil weight: about 5--12 tons 8. Coil diameter: 508-1500 mm or as per customer's request

A36 is an American standard carbon structural plate, which is subject to ASTM A36/A36M. This standard is applicable to riveting, bolting and welding structures for bridges and buildings, as well as general purpose structural steel quality carbon steel sections, plates and bars.

[Main use of SPHC material] Hot rolled steel plate products are widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries due to their high strength, good toughness, easy processing and good weldability. With the maturity of new control technologies such as hot rolling dimensional accuracy, shape and surface quality and the continuous emergence of new products, hot rolled steel plates and strips have been more and more widely used and become more and more competitive in the market.

DC01-A: Defects that do not affect the formability or surface coating are allowed, such as air holes, slight dents, small marks, slight scratches and slight coloring.

DC01-B: The better surface shall be free of defects that may affect the uniform appearance of high-quality paint or electrolytic coating. The other surface shall meet at least surface quality A.

The main application fields of DC01 materials include: automobile industry, construction industry, electronic equipment and household appliances industry, decorative purposes, canned food, etc.

SGCH Steel coils are classified according to their professional uses, including oil drum plates, bulletproof plates, shipbuilding plates, automobile plates, construction plates, machining plates, etc.

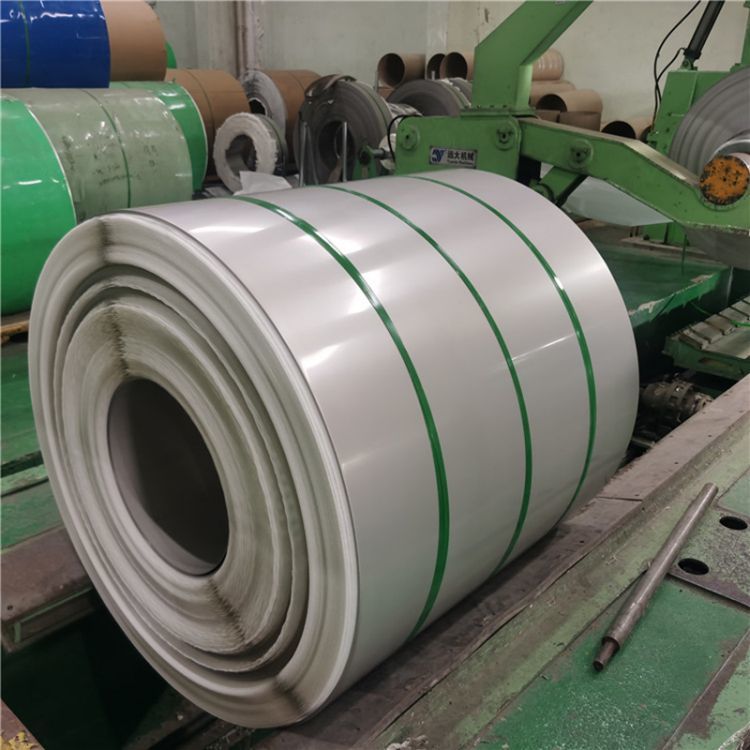

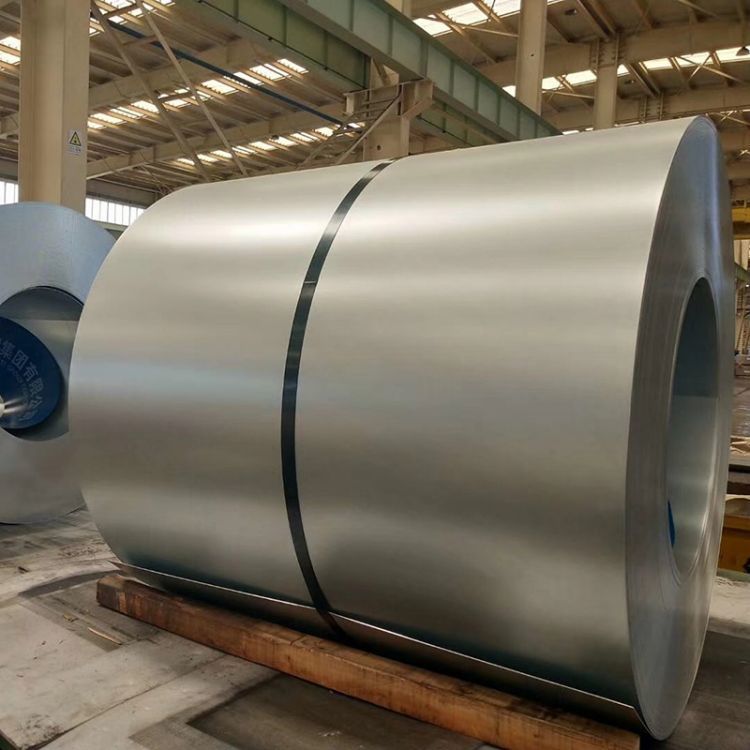

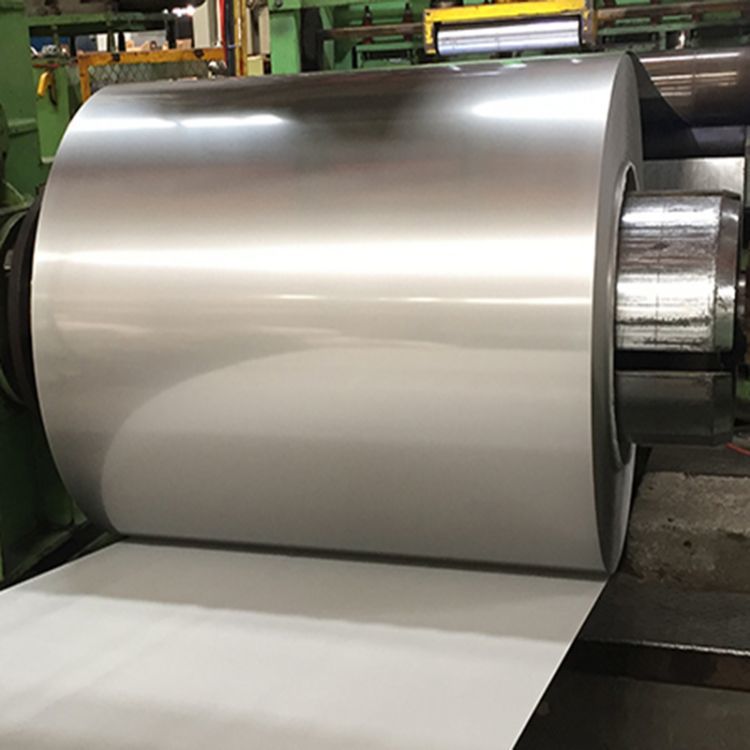

Specializing in the production and sales of carbon steel coils, factory direct sales, product grades and specifications are complete, and can certainly meet your various needs, welcome to consult.

Steel coils are classified according to their professional uses, including oil drum plates, bulletproof plates, shipbuilding plates, automobile plates, construction plates, machining plates, etc.

Specializing in the production and sales of carbon steel coils, factory direct sales, product grades and specifications are complete, and can certainly meet your various needs, welcome to consult

SPCC is commonly used cold rolled carbon steel sheet and steel strip.Cold coil is made of hot rolled coil at room temperature and below the recrystallization temperature, including plate and coil, of which the sheet delivered is called steel plate, also known as box plate or plate; the long length and delivered in coil is called steel strip, also known as coil plate.

201 stainless steel coil is mainly used for decorative tubes, industrial tubes and some shallow stretched products. Such as: oil waste gas combustion pipeline; Engine exhaust pipe; Boiler shell, heat exchanger and heating furnace components; Silencing parts for diesel engine; Boiler pressure vessel; Chemical transport vehicle; Expansion joint; Spiral welded pipe for gas furnace pipe and dryer, etc.

310S stainless steel coil is widely used in kiln, high-temperature furnace, boiler, furnace liner high-temperature equipment, such as kiln car, boiler liner, high-temperature furnace, high-temperature furnace tube, combustion machine liner, etc. It can be used for high-temperature equipment. The product is resistant to high temperature and heat. 310s stainless steel plate has good creep strength and can work continuously under high temperature. The working temperature of 310S stainless steel is 1200 ℃, and it can work continuously at 1100 ℃. It is mainly used to manufacture high temperature exhaust pipe, high temperature furnace, high temperature furnace liner, crematory furnace and other steel grades requiring heat resistance, as well as high temperature and high temperature contact parts.

304L stainless steel coil is mainly used in automobile accessories, hardware tools, tableware, cabinets, medical appliances, office equipment, weaving, handicrafts, petroleum, electronics, chemicals, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

316L stainless steel coil is commonly used in pulp and paper making equipment, heat exchanger, dyeing equipment, film processing equipment, pipes, materials used for the exterior of buildings in coastal areas, as well as watch chains and case of advanced watches.

430 stainless steel coil is used for building decoration, fuel burner parts, household appliances and household appliances. 430F is a steel with free cutting property added to 430 steel, mainly used for automatic lathes, bolts and nuts. 430LX adds Ti or Nb to 430 steel to reduce the content of C, which improves the processability and welding performance. It is mainly used in hot water tanks, hot water supply systems, sanitary appliances, household durable appliances, bicycle flywheels, etc.

904L stainless steel coil (super austenitic stainless steel) is a high alloyed austenitic stainless steel with very low carbon content. It has good corrosion resistance in dilute sulfuric acid and is specially designed for environments with severe corrosion conditions. It has high chromium content and sufficient nickel content. The addition of copper makes it have strong acid resistance, especially high resistance to chloride interstitial corrosion and stress corrosion cracking. It is not easy to appear corrosion spots and cracks. Its pitting resistance is slightly better than that of other steels. It has good processability and weldability, and can be used for pressure vessels.

2507 stainless steel coil is used in oil and natural gas industry; Offshore stone skyshatter oil platform (heat exchanger pipe, water treatment and water supply system, fire protection system, water spraying system, water stabilization system; petrochemical equipment; desalination (desalination) equipment (and high-pressure pipe and seawater pipe in the equipment). Mechanical and structural components that require both high strength and high corrosion resistance: fuel (waste) gas purification equipment.

Use of 2205 stainless steel coil: 1. The heater is generally used in the oil refining unit; 2. Chemical plant equipment pipeline; 3. Fast cooling cylinder for solid solution used in textile industry; 4. Seamless steel pipe for heat exchanger and condenser. 5. High pressure seamless steel pipe for food (gb-2000) is a high-quality carbon structural steel and alloy steel seamless steel pipe suitable for chemical equipment and pipes with working temperature of - 40~400 ° C and working pressure of 10~30ma. 6. Seamless steel pipes for geological drilling and oil drilling control. 7. Cracking pipe for petrochemical industry is used to transport high-temperature and high-pressure fluid on fertilizer equipment.

Cold rolled Non-Oriented silicon steel

Non oriented fully processed steels are iron-silicon alloys with varying silicon contents and have similar magnetic properties in all directions in the plan of the sheet. They are principally used for motors, generators, alternators, ballasts, small transformers and a variety of other electromagnetic applications.

Silicon steel is a kind of ferrosilicon soft magnetic alloy with extremely low carbon content. Generally, the silicon content is 0.5% ~ 4.5%.

Cold Rolled Silicon Transformer Steel

Electrical steel mainly consists of grain-oriented electrical steel and non-oriented electrical steel. Grain-oriented electrical steel widely used in transformer industry. Non-oriented electrical steel widely used in motor industry.

Transformer Grain Cold Rolled Non Grain Oriented Silicon Steel

We can offer different sizes silicon steel sheet and we can offer you different shapes as core and sheet. It is widely used in shielding installation area because its cheaper price.

Cold Rolled Grain Oriented Silicon Steel

Application:Widely used in transformers, generators, various household motors and micro-motors, etc.

ultra-thin non-oriented and grain oriented electrical steel sheet

ultra-thin non-oriented and grain oriented electrical steel sheet for transformer core silicon steel coilElectrical steel, also known as silicon steel, is a ferrosilicon soft magnetic alloy steel with very low carbon content, usually containing 0.5% to 4.5% silicon. The addition of silicon can increase the resistivity and maximum permeability of iron, and reduce the coercivity, iron loss and magnetic aging.

Electrical transformer grain oriented silicon steel

Grain-oriented silicon steel (Fe-Si steel; transformer steel; electrical steel) is a soft magnetic polycrystalline metallic alloy that is used as core material in electrical transformer cores and electrical motors.

Silicon steel EI lamination 2 3/8 EI 180 transformer EI core

Grain-oriented silicon steel (Fe-Si steel; transformer steel; electrical steel) is a soft magnetic polycrystalline metallic alloy that is used as core material in electrical transformer cores and electrical motors.

Oriented silicon steel

Thickness: 0.18mm, 0.20mm or as required

Width: 1200/1250 or as required

Length: As required

Standard: AISI,ASTM,DIN,JIS,GB,JIS,etc.

INCOLOY Alloy 825 Stainless steel coil

Incoloy 825 is a nickel iron chromium alloy, which is widely used in petroleum, natural gas and chemical processing industries. It has good corrosion resistance and can operate at higher temperatures than most stainless steels. Incoloy 825 is a completely austenitic nickel iron chromium alloy, stabilized by titanium and added with copper and molybdenum. Incoloy 825 is a general engineering alloy, which is resistant to acid and alkali metal corrosion in oxidation and reduction environments.

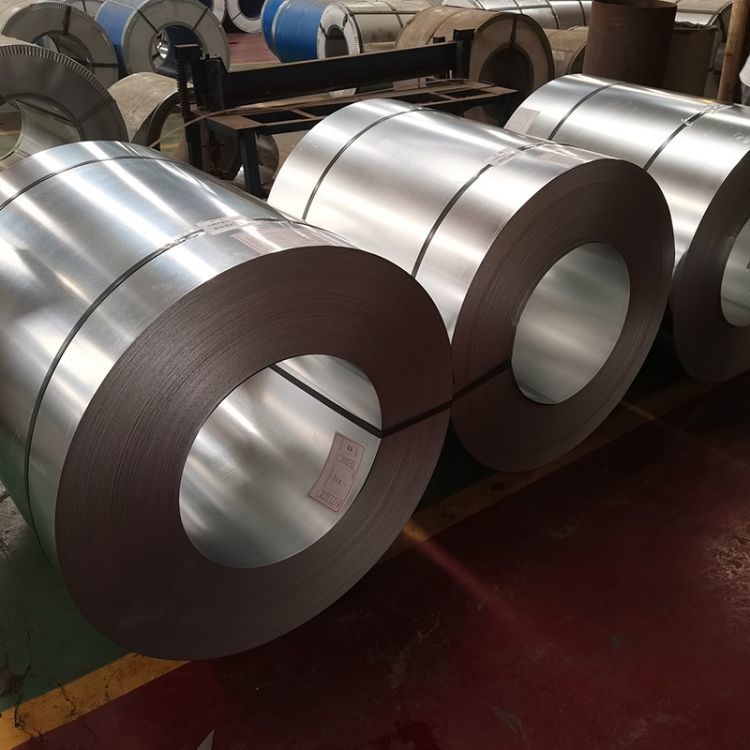

Q195 galvanized coil is a surface galvanized coil with yield strength of 195MPa.

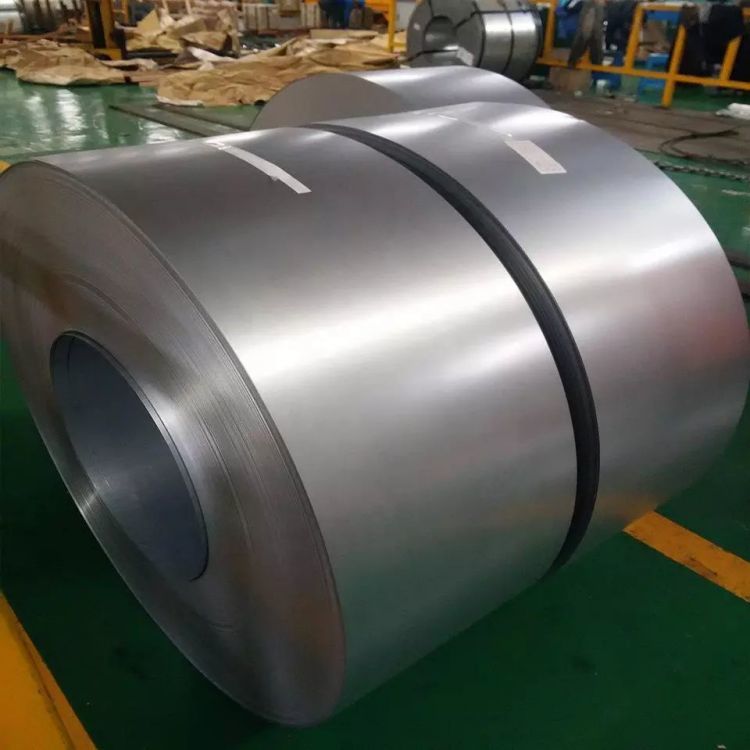

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

DC01 Galvanized steel sheet is used for automobiles, sanitary ware, food machinery, pressure vessels, nuclear power, chemical equipment, elevators, rail transit, machinery manufacturing, structural piping, and architectural decoration.

DX52D The construction industry is mainly used to manufacture anti-corrosion roof panels and roof gratings for industrial and civil buildings; In light industry, it is used to manufacture household appliance shells, civil chimneys, kitchen appliances, etc. In automobile industry, it is mainly used to manufacture corrosion resistant parts of cars, etc; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, frozen processing tools for meat and aquatic products, etc; It is mainly used for the storage and transportation of materials and packaging tools.

DX51D galvanized sheet material is a non-ferrous alloy mainly composed of zinc as the matrix and other elements. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and is resistant to atmospheric corrosion. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used cast zinc alloy is zinc aluminum copper magnesium alloy. Its casting process performance is good, and the cooling rate has little impact on the mechanical properties. It is mainly used to manufacture mechanical parts, toys, decorations, household appliances, etc.

Galvanized coil G550 belongs to high-strength series galvanized sheet, with high requirements for tensile strength and yield strength. Its minimum yield strength is 560Mpa, minimum tensile strength is 650Mpa, and zinc layer thickness is 275g/m2. It has strong corrosion resistance and is mainly used for building structures with high strength requirements, such as Z-shaped steel, C-shaped steel, floor bearing plate, etc.

Q235 galvanized coil is a surface galvanized coil with yield strength of 235MPa.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

About uses of Monel400 alloy: various heat exchange equipment, boiler feed water heaters, pipelines, containers, pumps, valves, shafts, etc. in petroleum and chemical processing, seawater desalination equipment, salt production equipment, propeller shafts, gasoline and water tanks, etc.

Hastelloy C-276 Stainless steel coil

Hastelloy C-276 alloy is one of the few materials that can be used in hot concentrated sulfuric acid solution It is mainly resistant to wet chlorine, various oxidizing chlorides, chloride solutions, sulfuric acid and oxidizing salts, and has good corrosion resistance at low and medium temperatures. Therefore, in the past 30 years, it has been widely used in harsh corrosive environments, such as chemical industry, petrochemical industry, flue gas desulfurization, pulp and paper making, environmental protection and other industrial fields.

Stainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.