2024-T3 Aluminum foil

2024 is a typical duralumin alloy in the aluminum-copper-magnesium system.

It is a heat-treatable alloy with high strength, easy to work, easy to turn, and moderate corrosion resistance.

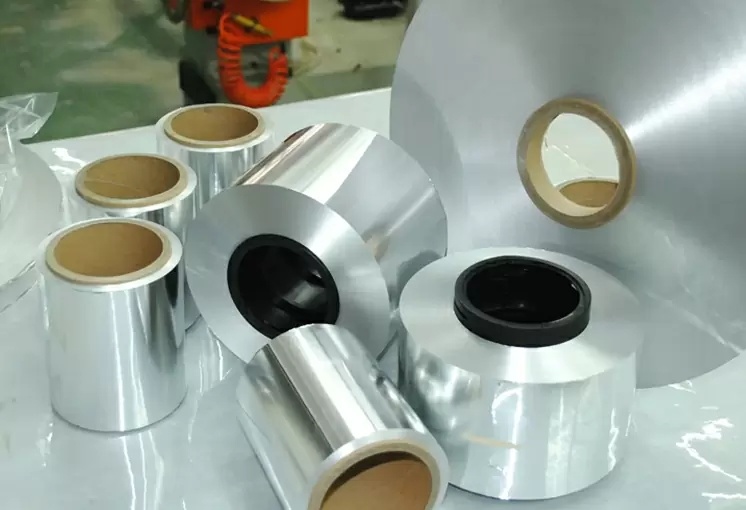

- Commodity name: 2024-T3 Aluminum foil

Keyword:

2024-T3 Aluminum foil

- PRODUCT DESCRIPTION

-

About the aluminum

The mechanical properties of 2024-T3 aluminum alloy can be significantly improved after heat treatment. 2024 is a typical duralumin alloy in the aluminum-copper-magnesium system. It is a heat-treatable alloy with high strength, easy to work, easy to turn, and moderate corrosion resistance. Main applications: aircraft structure, rivets, truck wheels, propeller components and other structural parts. 2024 aluminum alloy is a kind of high strength duralumin, which can be strengthened by heat treatment. It has medium plasticity under quenching and quenching state, good spot welding and gas welding, and has a tendency to form intercrystalline cracks. The alloy has good machinability after quenching and cold work hardening, and low machinability after annealing. Corrosion resistance is not high, often using anodic oxidation treatment and paint method or surface coated aluminum layer to improve its corrosion resistance. It is mainly used for making various high-load parts and components (but not including stamping parts and forgings), such as skeleton parts, skin, frame, wing ribs, wing beams, rivets and other working parts below 150℃.

Chemical composition: Silicon Si: 0.50; Cu: 3.8-4.9; Mn: 0.30-1.0; Magnesium Mg: 1.2-1.8; Chromium Cr: 0.10; Zinc Zn: 0.25; Aluminum Al: allowance;

2024 aluminum alloy, the main alloying elements are copper and magnesium. Applications where high strength but low weight ratio is required, and good fatigue strength. Not weldable, general processing performance. Because of poor corrosion resistance, aluminum-zinc splints are often used as protection, which results in reduced fatigue strength.

2025-T3 aluminum alloy has ultimate tensile strength of 58,000-62,000 psi (400-427 MPa) and yield strength of 39,000-40,000 psi (269-276 MPa). Elongation 10-15%.Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

Standard ASTM GB JIS AISI,EN Thickness 0.006mm(6micron) - 0.2mm (200micron) Width 120- 1500 mm (tolerance:± 1.0mm) Temper O,F, H12, 114,H18,H22, H24,H26,H32, etc Application Aluminum foil is widely used in food, beverage, cigarette, medicine, photographic plate, household articles, etc. It is usually used as its packaging material, electrolytic capacitor materials, insulation materials for buildings, vehicles, ships and houses.

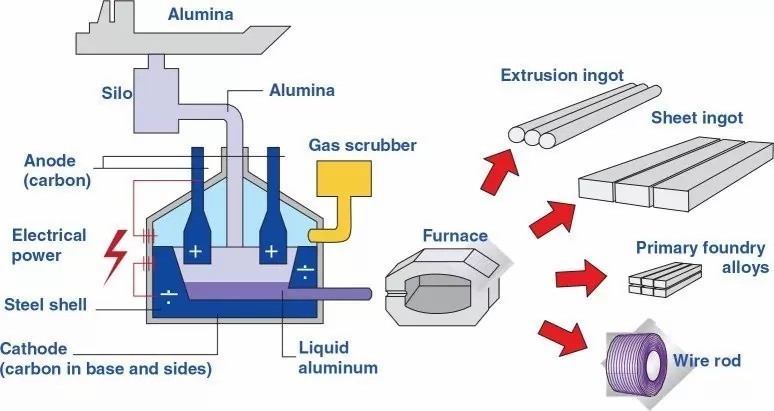

Price Term Ex-work, FOB, CFR, CIF, etc Delivery Time 20-30 days. Standard size is in stock,prompt delivery or as order's quantity. Package Export standard package, Carton box or wooden case, or waterproof paper, or as customer's request. The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM Aluminum Production Process

Packing and shipping

We can provide: wooden pallet packaging, wooden box packaging, steel strapping packaging, plastic packaging and other packaging methods. We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

Transportation method: We can provide container or bulk transportation, road, railway or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Factory appearance

It is a specialized manufacturer and seller of carbon steel, steel bars, stainless steel, galvanized, hot-rolled seamless steel pipes, precision seamless steel pipes, cold drawn seamless steel pipes, alloy pipes, special-shaped pipes, etc.

Application areas

Its products are suitable for various fields such as automobiles, motorcycles, power, machinery, hydraulic accessories, bearings, pneumatic components, oil cylinders, coal mines, conveyors, boiler equipment, pipelines, engineering, etc. Our company has 5 perforation units, 30 precision rolling machines, and 6 cold drawing machines.

Customer Reviews

Our products have won unanimous praise from many customers.

Application field

The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products